Uncategorized

Changing the way we think about control rooms

Mission critical operations have experienced a similar technology explosion as it relates to available technology for controlling and operating mission critical systems. However, the pace of adoption of new technology in these types of applications has been slower and more “cautious” compared to consumer applications.

This is understandable given the vital role that both public and industry mission critical operations play behind the scenes of our daily lives.

Some of the considerations that managers and leaders in these applications deal with on a daily basis include:

- Risk mitigation

- Existing infrastructure limitations

- Cost of operations

- Legacy control systems

- Technology compatibility

- and numerous other issues

The other major challenge is that, by definition, these operations are 24/7 and therefore cannot afford to be “offline” for an extended period of time to perform upgrades. And while some operations have fully redundant backup facilities, many do not, which often drives the need to build a new facility. As a result, upgrading a mission critical operation and physical control room becomes a much larger task, both from a planning perspective, and from a budgetary standpoint

Integrity of an operation rests in human hands

Another challenge is that most upgrade or “green field” projects go through a lengthy cycle of planning and execution. The technology specified at the outset of the project may no longer be the most optimal at the time of commissioning.

Lastly, there is the human element. Control room operators, and those who support mission critical operations, have challenging jobs. Ultimately the safety, efficiency and integrity of an operation rests in their hands, despite all of the technology and automation designed to make their job easier. As such, there is often a resistance to change the process; not because the operators don’t like new technology, but because they perceive it as a potential risk to something they are doing successfully on a daily basis. It is the old adage; “if it isn’t broke, why fix it?”

These and many other contributing factors have resulted in control rooms being relatively slow to adapt to the pace of technology change as compared to other applications.

Control Rooms and Technology Change

Some will argue that Mission Critical facilities are often on the leading edge of technology development. This was, and in some aspects, still is true. Historically, control systems for mission critical applications were often developed specifically for those applications. Companies focusing on this market were traditionally very focused and invested significantly in R&D to create solutions for control. However, these solutions often did not have a broad commercial application as they were purpose- built. As a result, the volume was fairly low which drove the cost of these systems and hardware to be significantly more than in the general commercial sector.

For example, think of a simple alarm management system. In a commercial building, alarm management systems are predesigned to integrate in the building control solutions and are often scaled up or down depending on the size of the facility and the systems that they control (electrical, fire suppression, water, security etc.). The core architecture of these systems does not typically vary from building to building.

If we compare this to a refinery, the difference is more pronounced. Each alarm management system, be it process control, fire suppression, security or emergency management has to be tailored specifically to that application considering the variability of operational models between refineries. To respond to this, vendors typically developed very specific and proprietary platforms. In part, this was done since there was not common software and hardware that was available to address all of the various operational needs.

Each operational position is specifically desig

Another reason was to protect the considerable investment into developing these solutions. This allowed vendors to maximize the utilization of their technology in their respective market segments.

This has driven the design of control rooms to be very task orientated. Each operational position in the control room is often very specifically designed to control a certain aspect of the operation. The software and, more importantly, the hardware, were tailored to support the specific tasks.

In larger operations, control room suites are developed to integrate the primary and support functions of the space. Until recently, this required all of the processors to be housed within the operator position. Gradually, control rooms have moved to remote CPU storage. However, the signal distribution was still specific to each operator position

The Technology Shift – Ready or Not, Here it Comes!

If we take a very broad look at the history of control rooms, there have been a few technology breakthroughs that really changed the way they function.

From the early days of control room applications (starting in the early 1900’s), control functions had a 1:1 ratio with process automation. In other words, each part in a process that an operator needed to observe or modify had its own dedicated direct physical link. The first major shift came in the 1960s and 1970s with the first applications of programmable logic, whereby multiple control functions were controlled through a single interface and controller.

The second shift came around the same time as visual content, (often limited to gauges and indicator lights) started to be consolidated in monitor displays through graphic interfaces culminating with the dominance of CRT monitors and large display walls for collaboration. This shift resulted in a large amount of physical infrastructure that needed to be considered when designing facilities.

Then in the late 90s came the shift to flat screen displays. This fundamentally changed how control rooms were designed and the impact on operator comfort was significant. Almost overnight, a brand new control room started looking “old” since the space allocated for CRTs was no longer required. Each of these examples drove new opportunities, but also different models in operational planning.

Two Major Developments Driving Change Today

The next major shift in control rooms is already here. And it has to do with the way we access and manage data within the operation.

- Video Management systems

The first development that is driving change is advanced video management systems. While video management systems (VMS) have been around for a long time, they have traditionally required “hard-coded” infrastructure into existing AV systems. This essentially meant that “programming” the video feeds and deciding what will be useable within the AV system needed to be decided upfront and coded into the video management system.

Flexibility for sharing content and cross-functional collaboration was limited without the ability to easily change over the life of the control room. New video management systems are significantly more flexible and easier to integrate into existing IT infrastructure. Programming of content sharing functions is simplified and can be done by the end-user. It can be tied into user-based permissions and can be associated with process control systems. Making video content “agnostic” enables some key operational advantages: Collaboration, content sharing, event-based video feed prioritization, consolidation of multiple displays into a single high-definition screen (dashboard approach), and remote monitoring to name a few.

This type of flexibility is also changing the way we think about audio visual hardware. Generally speaking, the norm in control rooms has traditionally been using large video displays, often consisting of multiple screens. This is used for common viewing, situational awareness and forsome system-wide process information displays. Often it was not easy to move content from the main display to a single (or multiple) operator position. The large displays also often drive the entire layout of the control room since accommodating the image size, visual sightlines and viewing cones directly impact the amount of real estate and the physical portioning of the operator consoles. The end result is that control room layouts are closely tied to the image layout of the common display wall. This is good; however, it limits the flexibility to adapt the operation to changing requirements

Of course, not all mission critical environments have this constraint and in a lot of cases the video wall is strictly used as an overview display; control room operators are not dependent on it for any mission critical control aspects.

An example where common displays often are closely tied into the operation is electrical transmission and distribution. In these applications operators are required to monitor a very large geography related to transmission lines. The SCADA system is often geography-based where sets of operators monitor certain geographical sections of the grid. In addition there is a supervisory and dispatch layer within the control room. As a result, the rooms are often laid out based on the geography and function. The conventional approach to image tiling would simply take the SCADA feed fora specific geography and display it on the appropriate portion of the large display. From an operator’s perspective, the number of screens that they are required to monitor is significant, so the “image real-estate” required for a position is quite large. Once all of the local screens are put in place, if a second row of screens is required, it becomes challenging to visually interact with the video wall in real-time

Another challenge is the operational change requirements that utility companies often face. With mergers and acquisitions, as well ongoing expansion of the transmission grids, the actual geography that needs to be controlled can vary significantly. Adapting to this change within the existing control room footprint can be very challenging, if not impossible. However, with flexible video management systems, at the very least the content management of expanding an operation can be managed more effectively

One approach of how this challenge is overcome is creating localized collaboration and situational awareness displays at the operator position. This is done by adding a tier of large displays above the primary operational displays at each position. In effect, a “localized display wall” is created that can be used by both the operator and other support functions during normal or upset scenarios. The localized common displays can also be added to functional clusters. This approach “decouples” the operator position from the geography of the grid and therefore the layout of the room. It is the flexible video management system that enables this approach.

While this is just on example, it shows how technology can change the way we think about designing an operation and, perhaps more importantly, how we can adapt to changing operational requirements. The bottom line is that VMS is enabling mission critical operations to be safer, more flexible and increasingly efficient. To be fair, it would be an oversimplification to say that VMS alone will deliver maximum benefits. There are other elements of operational planning and technology infrastructure that need to be considered during the design process

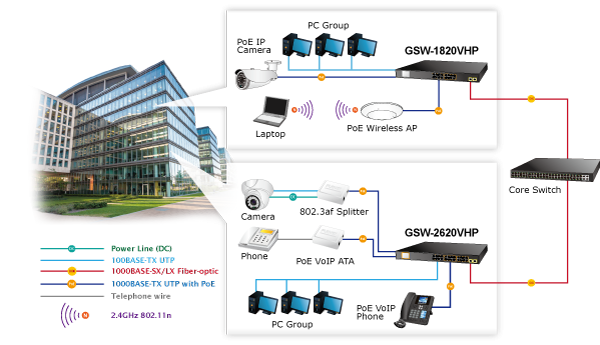

2. Fiber Optic Cabling

Fiberoptic cabling is nothing new. It has been around for years and has been extensively used in telecommunications, video and similar applications where an increasing amount of data distribution was required. For the most part, control rooms have not traditionally used fiber infrastructure; copper-based cabling has typically been utilized for data distribution requirements. This is because copper cabling has been sufficient for distributing specific data to dedicated control room positions, and the cost is significantly lower than fiber.

It was not until recently that fiber optic cabling has been used in control rooms in a significant way. The main reason for utilizing fiber optic infrastructure in the past was to accommodate applications that had a significant amount of bandwidth (such as managing significant amounts of video content).

Trong một môi trường quan trọng, có khả năng xem dữ liệu video không bị nén (không biểu hiện độ trễ hoặc suy giảm hình ảnh) là một lợi ích trong giám sát thời gian thực. Không có gì đáng ngạc nhiên khi việc áp dụng rộng rãi sớm cơ sở hạ tầng cáp quang ngày càng phổ biến trong các ứng dụng quân sự và giám sát để đưa ra được lượng thông tin được xử lý tại bất kỳ thời điểm nào và thực tế các quyết định thời gian thực đã được đưa ra phần lớn dựa trên phân tích dữ liệu từ hệ thống chỉ huy.

In a mission critical environment, having the ability to view video data that is not compressed (and therefore does not manifest latency or image degradation) was a significant benefit in real- time monitoring. It is not surprising that early widespread adoption of fiber optic infrastructure was prevalent in military and surveillance applications given the amount of information being processed at any given time and the fact that real-time decisions were being made based on a significant amount of external data

But there are other benefits that can provide significant advantages within a control room including greater flexibility for scaling the operation (increased video feeds, more monitoring positions, addition of critical feeds), as well as greater access control. Scalability is one of the biggest challenges in mission critical facilities as the cost of upgrading the operation is often significant. With fiber infrastructure, upgrades are easier to manage as the operation’s technology evolves

Access control continues to grow in relevance as cyber security becomes the focal point for mission critical facilities. In many industry applications (both public and private), cyber security standards and federally mandated requirements are becoming common place. And while many see the standards as restrictive and rigid, having a fiber infrastructure in place can provide flexibility while still meeting regulatory requirements. An example of how this type of infrastructure can change the way we think about mission critical operations can be found in the Air Traffic Control industry. When we think of an air traffic control tower (ATCT), we think of a very high stress, demanding environment where the visual, human interaction between a controller and incoming aircraft (not to mention the vast amount of technology required to provide additional operational information) all come together. All of us have seen them; the impressive structures carefully located at airports and designed to provide maximum visibility of the runways, taxiways, ramps and surrounding airspace. But a major change is coming. There are now airports that have remote, redundant ATCTs located at ground level and in rooms with no external visual sightlines. So how is this possible? The advances in managing video content, and the fact that a zero latency video feed is now available using fiber, is changing the way we can process information. It is also challenging the conventional approach of needing to physically see the information we need to make real-time decisions.

A similar example is remotely operated aircraft. The fact that a pilot can execute a mission half way around the world without physically being in the aircraft shows us just how far technology can be utilized.

Tiếng Việt

Tiếng Việt